High Visibility Safety Clothing - What is it and Why is it Important?

The principal purpose of safety clothing is to protect the wearer from harm.

People in industries where a significant proportion of the work occurs near traffic, cranes, other motorised vehicles, or working at night need to be seen in order to lessen the risk of injury and prevent accidents occurring in potentially dangerous situations.

For the Recovery Industry, operators spend a lot of their working lives in frequently dangerous situations as they carry out roadside work.

Being seen by other road users is key to safety, hence why high visibility clothing has a classification system to match the level of visibility within the working situation. This is encompassed in EN ISO 20471 certification.

Cardno was, until Aug 2017, a manufacturer of hi-vis safety clothing, which it sold alongside Dickies® & Portwest® hi-vis safety clothing ranges.

It does not matter which country a garment is manufactured in as long as the garment conforms to the relevant standard – for hi-vis clothing this is EN 20471.

The label of conformity, along with the CE mark will be in the garment. So read the label!

What is EN ISO 20471?

EN ISO 20471: 2013 High Visibility Clothing is an international standard for the safety requirements and test methods of hi-vis workwear and is applicable to high-risk situations.

It specifies requirements for 'high visibility clothing which is capable of visually signalling the user's presence' and assesses the suitability and durability of retro-reflective materials.

The 3 main components of hi-vis clothing

EN ISO 20471 covers the design and performance requirements of each element of a hi-vis garment.

There are usually 3 main components:

- The fluorescent material This especially boosts visibility during daylight hours but can also increase visibility at night.

- The reflective stripes Designed for visibility during the darker hours, reflective stripes require a light source to work and create retro-reflection. Essential for those working at night.

- The contrast material This is darker coloured parts of the garment that are less sensitive to dirt than the fluorescent material and reflective strips, without which the functionality of some hi-vis garments would diminish. The areas covered with the contrast fabric tend to be where dirt is most likely to build up.

EN 20471 High Visibility Garments: Class Levels

This standard categorises hi-vis garments into 3 classes and all garments should be labelled with the EN ISO 20471 icon, accompanied by the appropriate class number.

The selection and use of hi-vis should always be based on a risk assessment of the conditions and risks for a particular worker. The class of hi-vis workwear you need depends on the risk zone the worker is in, which in turn determines the amount of reflective tape and fluorescent material required.

Class 1: Lowest level of visibility

Items that commonly meet class 1 include hi-vis trousers when worn separately from other hi-vis garments.

Class 2: Intermediate level of visibility

Items that commonly meet class 2 include hi-vis sleeveless or short sleeved vests and polo shirts.

Class 3: Highest level of visibility

Items that commonly meet class 3 are hi-vis jackets, sleeved hi-vis vests, hi-vis overalls.

|

Class 2 |

Class 3 |

|

Sleeveless waistcoats, tabards, bib & brace, trousers |

Coats and jackets with sleeves, coveralls, two piece suits |

|

0.5m2 fluorescent material |

0.8m2 fluorescent material |

The advice from Cardno to wearers, within the Recovery Industry, is that you need a Class 3 jacket.

Only this class will give you the level of protection required by law, when working on roads where the speed limit is 50 mph or above.

How do you know what class your garment is? Check the label! If the label does not say 3 then the garment is not class 3!

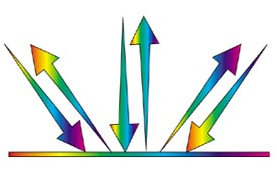

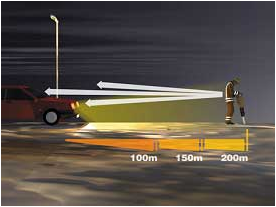

Reflective Stripes - What is Retro Reflection?

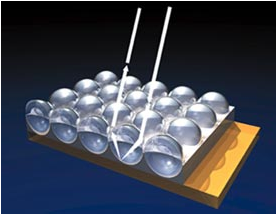

3M™ Scotchlite™ Reflective Materials use a technology known as retro-reflection. Retro- reflection occurs when light rays are returned in the direction from which they came.

Imagine a man is working at the roadside. A car is approaching with its headlights on. If the man were wearing a garment incorporating Scotchlite™ Reflective Material, a large amount of reflected light would be returned directly towards the original light source i.e. the car thus increasing the visibility of the worker to the driver.

Retro Reflective Technologies - 3M™ Scotchlite™

Glass lens technology utilizes millions of high performance glass beads that reflect light very effectively in all directions due to their spherical nature. Round glass beads provide 100% surface reflection, making it the most efficient way of reflecting light.

Some of the benefits of choosing Scotchlite™ Reflective Material incorporating Microscopic Glass Lens Technology are listed below.

- EN471 Compliance.

- Lightweight and comfortable, Scotchlite™ Reflective Materials offer the ultimate in wearability and can be up to 55% more lightweight than prismatic fabrics.

- Higher Performance Products are able to withstand high temperature washing - up to 92°C.

- Non orientation sensitivity enabling 360° visibility.

- High resistance to extremes of temperature.

- Flame Retardant Options.

Key requirements of EN ISO 20471

The standard covers the requirements for the base fabric colour, minimum areas for reflectivity, and placement of tape.

The requirements on the minimum area of reflective material can restrict the ability to adjust garments. For example, shortening trousers might reduce the area of fluorescent material too much. This also means that hi vis trousers shouldn't be tucked into boots when in use, as the garment may no longer comply.

The same goes for wearing a jacket unzipped so that the fluorescent & reflective stripes are obscured.

Three colours of fluorescent material are approved in the standard; yellow, orange and red. In addition to the surface area of each material, there are also requirements for the performance of these materials, as well as the degree of reflection from the reflective strips.

Physical properties including tensile strength, thermal resistance, and dimensional stability are also covered within the standard to ensure that all hi-vis is suitable for a range of working conditions where there is a high risk.

Although branding PPE is a great way of promoting and distinguishing your company on site, employers should take care when adding logos to hi-vis workwear.

This is because the areas of background or retro-reflective material that is covered will be excluded from the calculation of the required minimum area.

Ask your supplier to make sure that badges and logos do not detract from EN ISO 20471 compliance.

Can you be 100% confident that the High Visibility clothing you buy meets EN ISO 20471?

Portwest® regularly test samples from the market. Here are the 6 most common problems they encounter:

1. Problem: The fluorescent material does not meet the correct colour standard.

Solution: At Portwest®, every roll of fabric is tested to ensure it meets and exceeds the EN ISO 20471 standard requirements for colour. A spectrophotometer is used to measure the chromaticity – “colour intensity” of the fabric

2. Problem: Retro-reflective tape does not meet the minimum requirement 330 d/lux.

Solution: At Portwest®, every roll of tape is tested to ensure it meets and exceeds the EN ISO 20471 standard requirements. A retroflectometer is used to measure the coefficient of two rotating angles. EN ISO 20471 states the reading should not be below 330 (cd/lx.m2) however at Portwest® we insist on a reading of 400 (cd/lx.m2) plus.

3. Problem: The garment size is too small and does not have enough fluorescent material or reflective tape to meet the standard.

Solution: At Portwest®, all our products are generously sized and designed with the EN ISO 20471 standard requirements in mind to ensure full compliance.

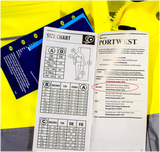

4. Problem: The garment label does not have the correct information displayed.

Solution: All Portwest® garment labels have the correct information displayed in accordance with EN ISO 20471 and ISO 13688 standard requirements.

5. Problem: The garment does not have a user information document accompanying the product. This is a mandatory requirement.

Solution: At Portwest®, all garments certified to EN ISO 20471 carry a user information document.

6. Problem: The garment does not display the notified body number so a customer cannot contact the test house where the garment was certified.

Solution: All Portwest® garments feature a notified body number on the user information document so a customer can contact the Independent Notified Body directly.

Hi-Vis Safety Clothing - Fit for Purpose

Contrary to what is now popular myth, high visibility clothing doesn’t need to be trendy it just needs to be practical - FIT FOR PURPOSE.

You can spend a fortune on clothing, but just remember if you have purchased Hi-Vis Clothing then it is to be seen, once the clothing has become dirty and can no longer be cleaned or that the reflective stripes have started to fall off, then it is no longer fit for purpose, regardless of the fact that the garment is not worn through.

At Cardno we believe in giving our customers a choice of quality/spend, but conformity to EN 20471 comes as standard.

See the Cardno Hi-Vis Safety Clothing range. Contact us if you could do with some more advice. We’re always happy to help.

- Cardno Sales Team