These Boots are made for Working!

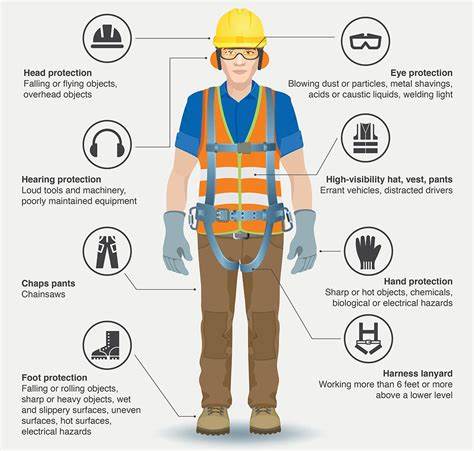

All trades people and those involved in jobs where there is a higher risk to personal safety, for example, the 'Construction' sector, should, 100%, wear the necessary/required PPE equipment whilst at work, of which, Safety Boots are an integral part.

Is it a legal requirement to provide safety boots?

The Personal Protective Equipment at Work Regulations 1999 say that, if a risk has been identified and cannot be controlled any other way, then protective equipment must be provided. This includes footwear.

ALL Types of PPE Equipment

There are several types of Safety Boots available on the market today, we hope this blog will help to explain what is available.

Firstly, Safety Footwear is regulated to conform to the Standard EN ISO 20345:2011.

It specifies basic and additional (optional) requirements for safety footwear that are used for general purpose. Footwear in accordance with EN ISO 20345 is intended to protect the wearer from bumps, crushing, falling or rolling objects, from walking into sharp or pointed objects, heat or cold, and hot substances. All safety boots must be manufactured and certified under this standard.

Each pair of boots should also carry a rating indicating the level of protection available. This is denoted by a two digit suffix, as per the descriptions below:

SB (Safety Basic) = This is the basic safety standard for footwear. These will have toe protection against a 200-joule impact.

S1 = As well as the basic toe protection, S1 will ensure that footwear has anti-static protection, is resistant to fuel oil and has energy absorption in the heel.

S2 = These have all the same protection as S1, plus the added protection of preventing water penetration and absorption of the uppers.

S3 = This as all the same protection as S2 level, plus mid-sole penetration resistance.

S4 = The same level of protection offered by S1 but with a moulded polymer/rubber upper (e.g. Wellington Boots) making them fully waterproof.

S5 = The same features as S4 footwear with the additional benefit of mid-sole penetration resistance.

In addition to this rating code, a manufacturer may add a further letter(s) indicating additional levels of protection.

For example, if you see SB P, this is indicating that the boot has an optional feature. So, you get the basic protection of SB plus you get the addition of P. The P stands for Penetration Resistance. There are a number of these abbreviations that can be tagged onto a rating, the more commonly used ones that you will come across are listed below.:

Common additional abbreviations:

|

Additional Letter |

Description |

| P | Penetration resistance |

| C | Conductive |

| A | Anti-static |

| I | Electricity insulating footwear |

| WR | Water Resistance |

| M | Metatarsal Protection |

| AN | Ankle Protection |

| CR | Cut Resistant Upper |

| WRU | Water Penetration and Water Absorption Upper |

| HRO | Out-sole Resistance to Hot Contact |

| FO | Oil & Petrol Resistance |

Slip Resistance:

Anti-Slip footwear is also becoming more and more requested on building sites, in hospitals, food manufacturing plants and a wide host of other settings. And for good reason, slips, trips and falls make up an astonishing 43% of all serious work-related injuries reported to the HSE. Footwear that has an anti-slip rating will be added to the safety boot rating and will have been tested according to a set of European test standards written into EN ISO 20344:2004 (A1: 2007).

For example, you may see the following S3 SRC. These are the three codes used for slip resistance testing.

SRA – tested on ceramic tile wetted with dilute soap solution.

SRB – tested on smooth steel with glycerol.

SRC – tested under both the above conditions.

It should be noted that these test surfaces are not wholly representative of all underfoot surfaces, so additional information may be needed to help to identify the best slip-resistant shoes for your particular environment.

So, you can see there are a lot of options available! But, hopefully, we have clarified that, by checking the coding applicable to each pair of boots, you will be able to narrow down to what you really do need.

Giffard Newton & Sons Limited, boot makers since 1854. With more than 167 years dedicated to the craft of making boots, they are still inspired to innovate their techniques to always ensure the absolute best quality products. From choosing only quality components, to using age old techniques in production, their primary focus has never waivered.

As a proud British company, their sense of duty dates back to the first world war, at which time they began making boots for soldiers and emergency service personnel. More than a century later, key works and military personnel continue to still choose Giffard Newton & Sons boots.

Cardno is proud to promote Giffard Newton & Sons safety boots.

- Cardno Sales Team